7 Non metallic shells and non-metallic components of shells

7.1 general rule

7. 1. oneScope of application

The requirements specified in this chapter and 26.7 shall apply to non-metallic enclosures and non-metallic components of enclosures related to explosion-proof types.

Note 1: Some examples of non-metallic components of enclosures related to explosion-proof types include sealing rings for "e" - shaped enclosures or "t" - shaped enclosure covers, fillers for "d" - shaped or "e" - shaped cable entry devices, sealing rings for cable entry devices, seals for "e" - shaped switch actuators, etc,

Note 2: In some supplementary or modified sections of this document, the requirements for "non-metallic components of enclosures" in this chapter apply to non enclosure components related to explosion-proof types, such as "d" type insulation sleeves and "e" type terminals.

7.1.2Material requirements

7.1.2.1general rule

According to the documents specified in Chapter 24, the material of the shell or shell components should be specified

7.1.2.2Plastic materials

The technical requirements for plastic materials should include the following:

a)The name or registered trademark of the resin manufacturer or synthesizer,

b)Material identification, including model and color,

c)Possible surface treatments, such as coating with varnish, etc,

d)The temperature index TI corresponding to the 20000 h point of the thermal stability curve, according to GB/T 11026 1 When tested according to GB/T 11026.2 and GB/T 9341, the bending strength shall not decrease by more than 50% If the material does not break during the test before heat exposure, the temperature index should be determined based on the tensile strength measured by the lA or lB type test bar specified in GB/T 1040.2. The relative heat index (R TI - mechanical strength or R TI - mechanical impact) can be replaced by the value determined by ANSI/UL 746B.

e)When applicable, data support in accordance with 7.3 (UV resistance).

The data source for the above characteristics should be determined.

Note 1: This document does not specify the verification of whether plastic materials meet the manufacturer's technical requirements.

Note 2: When selecting plastic materials, some manufacturers have noted that the types and percentages of fillers, flame retardants, and UV stabilizers have a significant impact on the performance of plastic materials.

Note 3: Material traceability guidelines can be found in GB/T 3836.21. Manufacturers who plan to use "fingerprint" methods (such as infrared scanning or oxygen index) to trace plastics will need to pay attention to this during type testing in order to obtain benchmark information.

7.1.2.3Elastic material

The technical requirements for elastic materials should include the following:

a)The name or registered trademark of the resin manufacturer or synthesizer;

b)Material identification, including model and color;

c)Possible surface treatments, such as varnish coating, etc;

d)Continuous operating temperature (COT);

e)When applicable, data support in accordance with 7.3 (UV resistance)

The data source for the above characteristics should be determined.

Note 1: This document does not specify the verification of whether the elastic material meets the manufacturer's technical requirements.

Note 2: When selecting elastic materials, some manufacturers have noted that the types and percentages of fillers, flame retardants, and UV stabilizers have a significant impact on the performance of elastic materials.

Note 3: Material traceability guidelines can be found in GB/T 3836.21. Manufacturers who plan to use "fingerprint" methods (such as infrared scanning or oxygen index) to trace plastics will need to pay attention to this during type testing in order to obtain benchmark information.

7.1.2.4Adhesive material

The technical requirements for adhesives should include the following:

a)The name or registered trademark of the adhesive manufacturer;

b)Material identification, including model number;

c)Continuous operating temperature (COT),

Determine the data source for the above characteristics.

Note: This document does not specify the verification of whether the adhesive meets the manufacturer's technical requirements.

7.2 thermal stability

7.2.1Thermal stability test

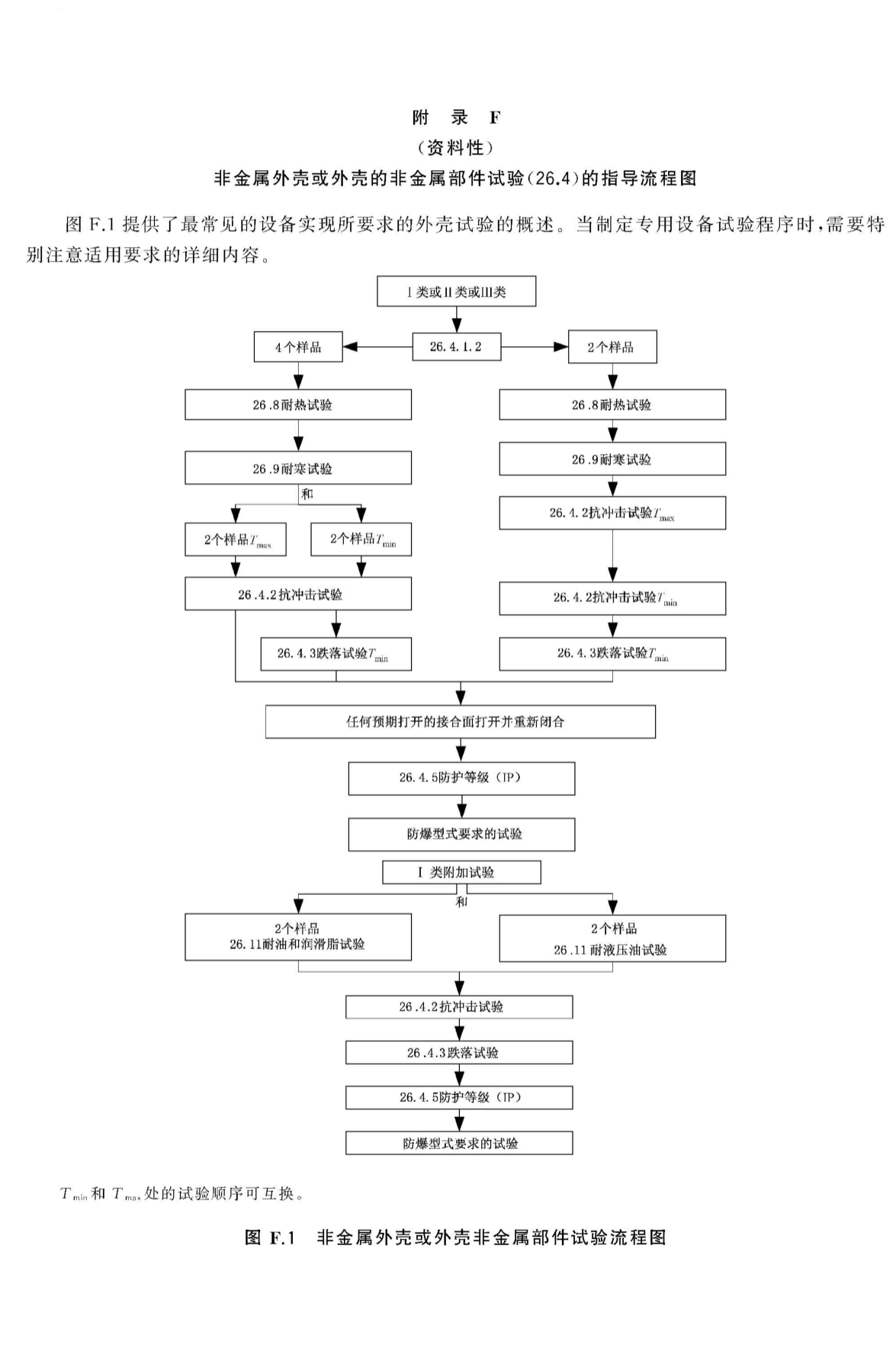

The heat resistance test and cold resistance test should be conducted according to 26.8 and 26.9. The experimental sequence is shown in 26.4.

No platform or individual is allowed to plagiarize or repost!

|

||||||

|

||||||